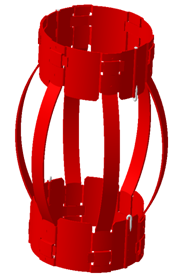

Bow spring centralizers

Centralizers are slightly larger than the wellbore, they can provide complete centralization in vertical and deviated wells. These centralizers can be installed directly during casing run through its special hinge feature. The bows of these centralizers go through a special heat treatment to provide high restoring forces and are available in both welded and non-welded bow design with hinged and slip-on type. These can be directly installed over coupling applications.

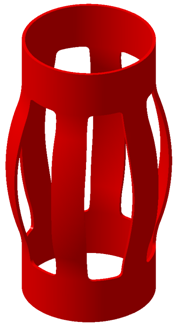

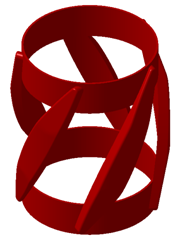

Single Piece Centralizers

A single piece construction designed for close tolerance & under-reamed hole sections that provides superior standoff with high product performance level. Zero starting and running force with higher restoring force enables casing to reach maximum depth. Single piece centralizers ensure effective cementing which is crucial for well integrity and zonal isolation.

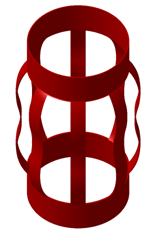

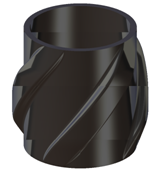

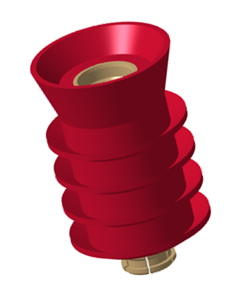

Solid / Rigid Centralizers

One-piece solid centralizer handles wear resistance and high impact loads during casing run. Various types of solid centralizers are recommended for different well services. These centralizers are recommended for highly deviated and horizontal wells having greater axial and lateral load capability with positive standoff. This centralizer is used to center the casing in the wellbore to guarantee replacement of the mud by cement. Provides uniform annular clearance & reduces drag. Provides positive standoff for better cementation.

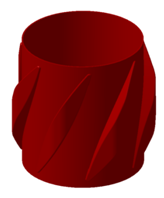

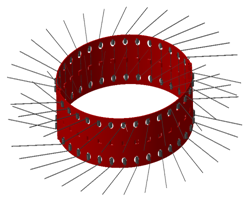

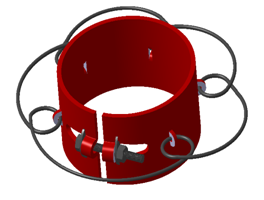

Stop Collar

These devices are used to restrict the movement of casing centralizers during casing run in open hole / cased hole. Hinged type stop collars used where annular clearance is high & used in both cased hole and open hole applications. Slip on type stop collars used in close tolerance applications where high axial load is a key factor.

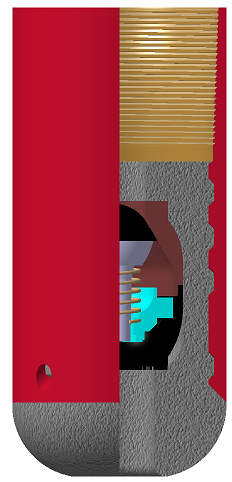

Floating Equipment

These are used in well construction and controls back pressure of cement from the annulus with its valves. Float collar gives an extra check point for both controlling of cement flow and back pressure. Provides casing buoyancy during running in wellbore and act as a landing pad for cementing plugs. These tools play vital role during cementing operation such as restrict back flow during cementing operation, it guides the casing string, minimizes mud contamination and aids in mud displacement.

Casing shells can be supplied based on customer engineering drawings.

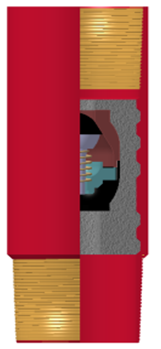

Cementing Plugs

These are used to separate the cement slurry from other fluids, reducing contamination and maintaining predictable slurry performance. The top plug has a solid body that provides positive indication of contact with the landing collar and bottom plug through an increase in bump pressure. Cementing Plugs are used for cleaning drilling fluids from the casing. Plugs are PDC drillable & feature a rubber diaphragm. They prevent over displacement of cement slurry and help in separating cement from the drill mud.

Casing accessories

NextWell offers accessories which help smoothen and simplify the entire operation of casing and cementing by adding robustness and closure and ultimately leading to a better bonding required for casing and cementing in the deep surface.

Casing shells can be supplied based on customer engineering drawings.